Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

GE Profile washer makes a humming sound in Agitation mode that seems to be coming from the back of the washer, not the motor. The motor make no attempt to rotate in agitate mode. In Spin cycle, the motor turns the basket about 1-1/2 turns then appears to bind so that the outer basket twists, then the spin stops. Opening and closing the lid will cause repeated 1-1/2 turns, but that's as far as it turns. Just like the motionless basket in Agitate mode, after the basket makes the 1-1/2 turns, there is a humming that sounds like it's coming from the back of the washer. The belt looks good, the water fill valve and the emptying pump appear to be working okay. In 2006, while under warranty, GE replaced the whole drive system with an upgrade kit that included a clutchless motor and new transmission. They left the old transmission, which the repairman said was probably okay. Anyway, what could be today's problem? Thanks

|

|

|

|

|

|

Rank: Advanced Member

Groups: Expert

Joined: 10/16/2012(UTC)

Posts: 3,806

Was thanked: 7 time(s) in 7 post(s)

|

With washer off, try rotating the motor pulley by hand. In the CCW direction (viewed from below) it should be easy to rotate and this will cause the agitator to go back and forth. In the CW direction, it should release the brake and cause the transmission and basket to rotate. It will be a little more difficult in this direction and you need to use two hands to keep the pulley moving as the brake will grab as soon as you stop rotating. This will rule out a transmission problem. There should be nothing electrical in the back of the washer to make a humming sound. It could be a faulty control board behind the control panel that may sound like it's coming from the back of the washer. The motor upgrade has a capacitor and relay that should be mounted on the right side behind the front panel. There may be a problem with one of those items. Are you sure the humming is not coming from the motor?

Eric

|

|

|

|

|

|

Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

Originally Posted by: fairbank56  With washer off, try rotating the motor pulley by hand. In the CCW direction (viewed from below) it should be easy to rotate and this will cause the agitator to go back and forth. In the CW direction, it should release the brake and cause the transmission and basket to rotate. It will be a little more difficult in this direction and you need to use two hands to keep the pulley moving as the brake will grab as soon as you stop rotating. This will rule out a transmission problem. There should be nothing electrical in the back of the washer to make a humming sound. It could be a faulty control board behind the control panel that may sound like it's coming from the back of the washer. The motor upgrade has a capacitor and relay that should be mounted on the right side behind the front panel. There may be a problem with one of those items. Are you sure the humming is not coming from the motor?

Eric Thanks for that helpful info & Qs. I've been out all day and just now got to follow your reply. It will be Thursday afternoon before I can follow-up to this post and try something else. But we did check a few minutes ago that the pulley rotated fairly freely in both directions, with the agitator working when rotated CCW and the drum turning in the CW direction. The hum is probably coming from the motor and was reflecting off the back panel of the cabinet and appeared to be from somewhere else. FYI, there is no smell or odor of any kind that would indicate a fried motor. I just now read all the old posts whose links I found at the bottom of your reply. One dealt with a direct drive model called a Hydrodrive. Although mine has a transmission, some of the other symptoms are similar, such as lots of small bits of rubber under the washer, which I have, wherein the motor sensed belt slippage and would not run. But since the motor does not attempt to run in agitate mode, there is no opportunity for it to detect belt slippage, or so it would appear. I can see that the top edge of the belt is frayed exactly as described in one of the old posts. When I return this afternoon, I'll have a new belt with me just in case that is the culprit. I'm thinking I will first try the reset technique for the Hydrodrive motor to see if that will work for me. And I'll look to see if I have any of the blinking lights mentioned in the troubleshooting for the Hydrowave. I'll do that before I remove the belt. If no change, I'll remove the belt and see if the motor will run in spin cycle mode w/o a belt. If it does, I'll put enough water in it to see if it the motor will also run in agitate mode w/o a belt. If both of those work, I'll install the belt and see if it will still run. If the motor doesn't run w/the belt off, I suspect I either have a bad motor or it's not getting power. If it runs with the belt off but not with the new belt on --- I'm not sure what that means. Next I'll look for the capacitor & relay that you mentioned, but I'm not sure how to troubleshoot them. I did notice a small relay midway in a wiring harness along the inside of the cabinet. If the motor is the possible problem, I'm wondering if the person who replaced the motor in 2006 was incorrect when he told me it was a clutchless upgrade. My motor looks identical to the WH49X10035 shown on your site as having a clutch. The large round thick metal device above my pulley certainly looks like the clutch in your photo! This afternoon I'll look for a motor model # and check to see if it's in the WH49X10035 replacement list. In the meantime, if my rambling has not been too severe, maybe you will see this response and suggest some other sequence of action when I return this afternoon with a new belt. Thank you.

|

|

|

|

|

|

Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

Originally Posted by: fairbank56  With washer off, try rotating the motor pulley by hand. In the CCW direction (viewed from below) it should be easy to rotate and this will cause the agitator to go back and forth. In the CW direction, it should release the brake and cause the transmission and basket to rotate. It will be a little more difficult in this direction and you need to use two hands to keep the pulley moving as the brake will grab as soon as you stop rotating. This will rule out a transmission problem. There should be nothing electrical in the back of the washer to make a humming sound. It could be a faulty control board behind the control panel that may sound like it's coming from the back of the washer. The motor upgrade has a capacitor and relay that should be mounted on the right side behind the front panel. There may be a problem with one of those items. Are you sure the humming is not coming from the motor?

Eric Thanks for that helpful info & Qs. I've been out all day and just now got to follow your reply. It will be Thursday afternoon before I can follow-up to this post and try something else. But we did check a few minutes ago that the pulley rotated fairly freely in both directions, with the agitator working when rotated CCW and the drum turning in the CW direction. The hum is probably coming from the motor and was reflecting off the back panel of the cabinet and appeared to be from somewhere else. FYI, there is no smell or odor of any kind that would indicate a fried motor. I just now read all the old posts whose links I found at the bottom of your reply. One dealt with a direct drive model called a Hydrodrive. Although mine has a transmission, some of the other symptoms are similar, such as lots of small bits of rubber under the washer, which I have, wherein the motor sensed belt slippage and would not run. But since the motor does not attempt to run in agitate mode, there is no opportunity for it to detect belt slippage, or so it would appear. I can see that the top edge of the belt is frayed exactly as described in one of the old posts. When I return this afternoon, I'll have a new belt with me just in case that is the culprit. I'm thinking I will first try the reset technique for the Hydrodrive motor to see if that will work for me. And I'll look to see if I have any of the blinking lights mentioned in the troubleshooting for the Hydrowave. I'll do that before I remove the belt. If no change, I'll remove the belt and see if the motor will run in spin cycle mode w/o a belt. If it does, I'll put enough water in it to see if it the motor will also run in agitate mode w/o a belt. If both of those work, I'll install the belt and see if it will still run. If the motor doesn't run w/the belt off, I suspect I either have a bad motor or it's not getting power. If it runs with the belt off but not with the new belt on --- I'm not sure what that means. Next I'll look for the capacitor & relay that you mentioned, but I'm not sure how to troubleshoot them. I did notice a small relay midway in a wiring harness along the inside of the cabinet. If the motor is the possible problem, I'm wondering if the person who replaced the motor in 2006 was incorrect when he told me it was a clutchless upgrade. My motor looks identical to the WH49X10035 shown on your site as having a clutch. The large round thick metal device above my pulley certainly looks like the clutch in your photo! This afternoon I'll look for a motor model # and check to see if it's in the WH49X10035 replacement list. In the meantime, if my rambling has not been too severe, maybe you will see this response and suggest some other sequence of action when I return this afternoon with a new belt. Thank you.

|

|

|

|

|

|

Rank: Advanced Member

Groups: Expert

Joined: 10/16/2012(UTC)

Posts: 3,806

Was thanked: 7 time(s) in 7 post(s)

|

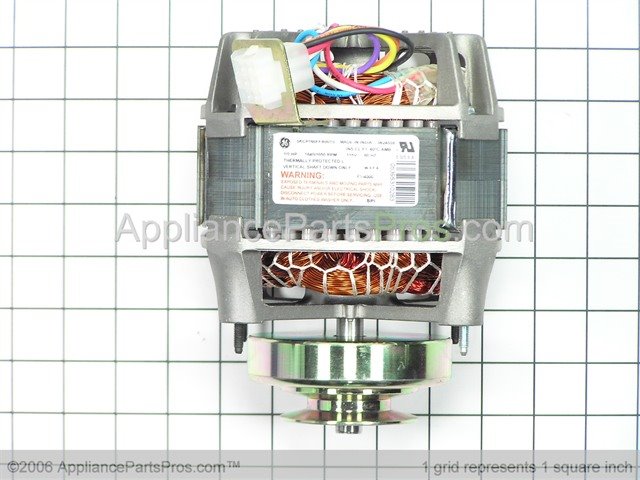

Your system does not have the motor/inverter of the hydrowave type that has the error code LED nor does it have a reset feature for the motor. Do you have a multimeter? One will likely be needed to troubleshoot this problem. If this is the motor you have, it is the correct replacement for your washer. The old motor that they removed from your washer is totally different looking. Eric

|

|

|

|

|

|

Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

Originally Posted by: fairbank56  Your system does not have the motor/inverter of the hydrowave type that has the error code LED nor does it have a reset feature for the motor. Do you have a multimeter? One will likely be needed to troubleshoot this problem. If this is the motor you have, it is the correct replacement for your washer. The old motor that they removed from your washer is totally different looking. Eric  Yes. The motor looks like the picture and I have a multi-meter. FYI, the motor nameplate shows: 5KCP160FFA001S, UPC 02491110338, 1/2 Hp 1640/1050 RPM. Despite the rubber bits on the floor and a slight fraying on the top belt edge, I noticed that the belt doesn't look worn and is still riding at the outside of the pulley.

|

|

|

|

|

|

Rank: Advanced Member

Groups: Expert

Joined: 10/16/2012(UTC)

Posts: 3,806

Was thanked: 7 time(s) in 7 post(s)

|

I would first check motor winding resistances. Unplug motor connector and check at motor receptacle. Orange to blue should be about 2.8 ohms, orange to white 5.9 ohms, black to red 4.7 ohms, black to violet 6.6 ohms, yellow to orange 0.0 ohms. At the harness connector check between yellow and white. This checks the relay coil which should be about 3.35 thousand ohms.

You can place the washer in service mode so that you can set it for spin, agitate low, agitate high directly. Press/hold start button and rotate dial 180°, release start button, all LED's should light up. Rotate dial one click to the left will be spin high, one more click is pump, one more click is fast agitate and one more left is slow agitate. With motor unplugged, you should be able to hear the relay click when switching between agitate low and high. If motor windings check out and relay is operating, you will need to make some voltage measurements.

Eric

|

|

|

|

|

|

Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

Originally Posted by: fairbank56  I would first check motor winding resistances. Unplug motor connector and check at motor receptacle. Orange to blue should be about 2.8 ohms, orange to white 5.9 ohms, black to red 4.7 ohms, black to violet 6.6 ohms, yellow to orange 0.0 ohms. At the harness connector check between yellow and white. This checks the relay coil which should be about 3.35 thousand ohms.

You can place the washer in service mode so that you can set it for spin, agitate low, agitate high directly. Press/hold start button and rotate dial 180°, release start button, all LED's should light up. Rotate dial one click to the left will be spin high, one more click is pump, one more click is fast agitate and one more left is slow agitate. With motor unplugged, you should be able to hear the relay click when switching between agitate low and high. If motor windings check out and relay is operating, you will need to make some voltage measurements.

Eric Thanks for that info. Ohm values were within 0.1 Ohm of your spec on all items EXCEPT an open circuit between orange & white to the relay coil instead of 3350 ohms. (Washer was unplugged when I did the relay coil measurement.) All the Service Mode functions provided the desired action and sounded and looked normal EXCEPT slow agitate, which just gave a hum but no motor running. I was so glad to hear the motor running at all, but when slow agitate was a no-show it was quite a bummer. I repeated to be sure. Rats! I could hear the relay click as you mentioned. What next?

|

|

|

|

|

|

Rank: Advanced Member

Groups: Expert

Joined: 10/16/2012(UTC)

Posts: 3,806

Was thanked: 7 time(s) in 7 post(s)

|

Sounds like the relay is faulty if the coil is open. Are you sure it's the relay behind the front panel that you are hearing and not a relay on the control board behind the user control panel? When low speed is selected, the relay is energized to select the low speed start winding and redirect power up to the control board. Do you have your meter set properly to read that high ohms value? Even if the relay is energizing, it could be a bad relay contact. Remove all the tape from around the relay and look through the clear relay cover for burnt contacts.

Added: They made some of these motor upgrade kits with relays made for 240vac coil voltage. Although they do work on 120vac, they should not be used. The coil resistance on the 240vac relays will read 13,600 ohms.

Eric

|

|

|

|

|

|

Rank: Member

Groups: Registered

Joined: 6/12/2013(UTC)

Posts: 8

|

Originally Posted by: fairbank56  Sounds like the relay is faulty if the coil is open. Are you sure it's the relay behind the front panel that you are hearing and not a relay on the control board behind the user control panel? When low speed is selected, the relay is energized to select the low speed start winding and redirect power up to the control board. Do you have your meter set properly to read that high ohms value? Even if the relay is energizing, it could be a bad relay contact. Remove all the tape from around the relay and look through the clear relay cover for burnt contacts.

Added: They made some of these motor upgrade kits with relays made for 240vac coil voltage. Although they do work on 120vac, they should not be used. The coil resistance on the 240vac relays will read 13,600 ohms.

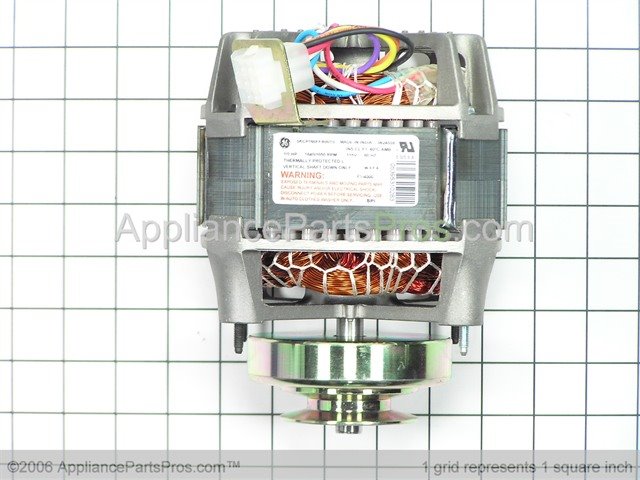

Eric :) Eric, Taa Daa! Problem appears solved, but not the path we expected. As soon as I touched the wires near the relay one of the double yellow ones going to the capacitor spade connector popped out, showing a burnt end. I suspect the repetitive action of the moving tub support around which the wire bundles are wrapped, combined with a very short wire from the relay to the rigid capacitor so it had no wiggle room, a factory installation that had the relay literally supported by the double yellow wires going to the capacitor, and the factory forcing two wires into a single-wire spade lug so one was not fully crimped, gradually caused one the yellow wires to flex and the strands to break individually until there were a few strands left. Those few chose this week to go Poof. The body of the relay does look a little cloudy inside, but no sign of burned contacts. I did some imagineering as I retaped the wires so that the relay weight is supported by the wire bundle coming down from the top of the machine, yet everything is free to move as much as the support rod can move. Once the yellow wires were repaired, I measured 3200 ohms from white to yellow at the motor plug. Next, all the functions passed in Service Mode. We just completed an uneventful wash load, which is a good thing. Happy --happy --- happy! The photo is pretty much as I found things when I went to see about the relay and discovered the broken yellow wire, except the capacitor bracket was tight. It's a wonder the wire didn't break long ago. I also noticed that the tape was quite chafed where it contacted the rod support at the bottom, so I reinforced that area. So thanks loads --- pun intended --- for your knowledge and assistance to stick with me thru this. If you will send me your mailing address, I'd like to send a token of my appreciation ... or at least make a charitable donation in your honor. Thanks again. Steve Stephenluck attached the following image(s):

|

|

|

|

|

|

Forum Jump

You can post new topics in this forum.

You can reply to topics in this forum.

You can delete your posts in this forum.

You can edit your posts in this forum.

You cannot create polls in this forum.

You can vote in polls in this forum.

Important Information:

The AppliancePartsPros.com uses cookies. By continuing to browse this site, you are agreeing to our use of cookies.

More Details

Close